Production of eco-friendly concrete incorporating rice husk ash and polypropylene fibres

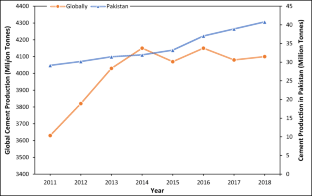

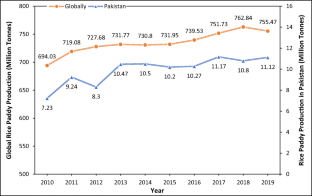

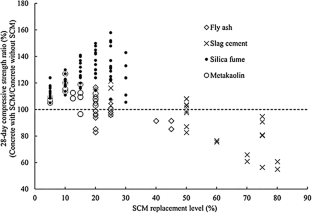

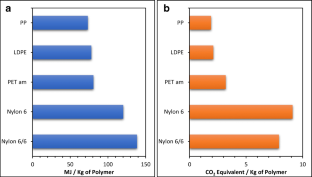

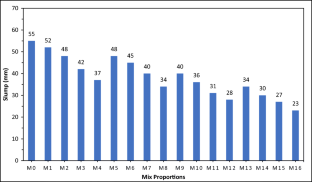

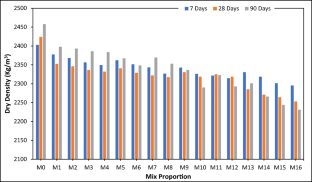

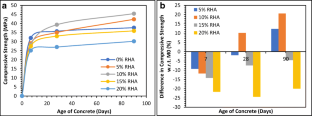

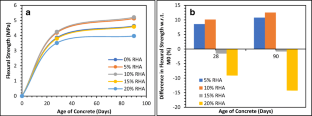

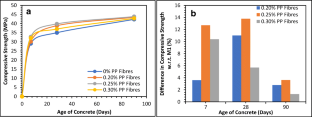

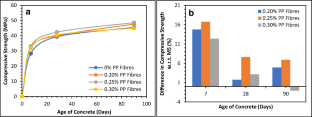

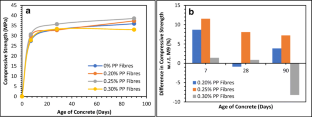

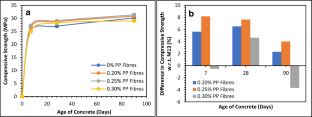

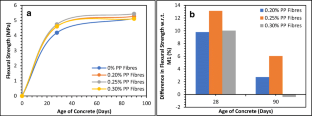

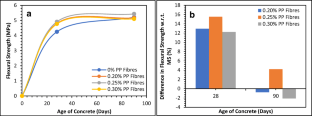

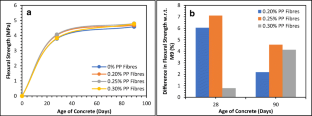

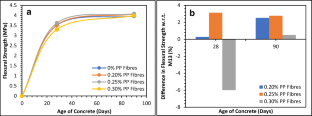

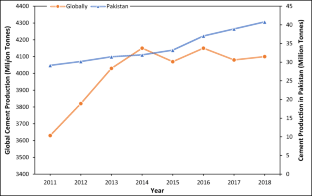

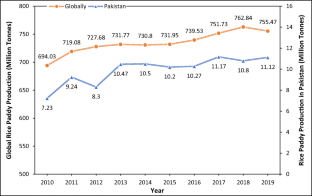

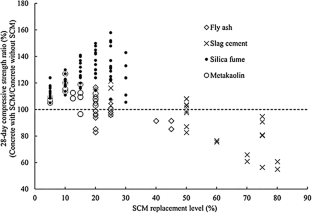

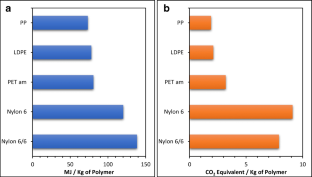

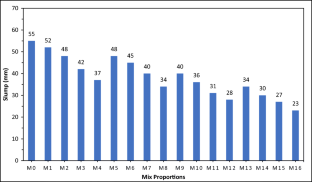

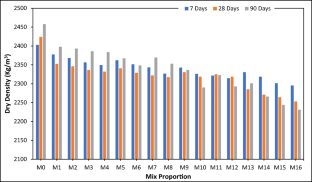

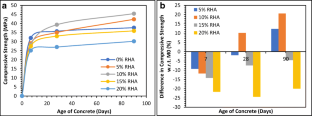

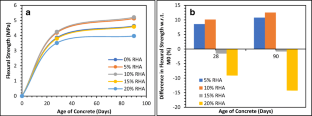

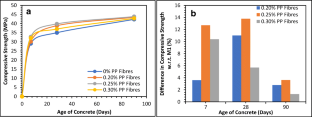

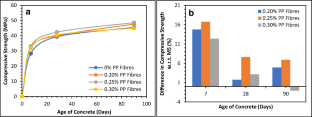

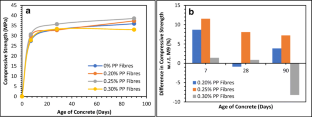

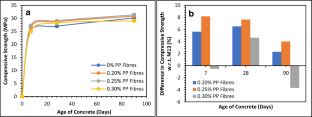

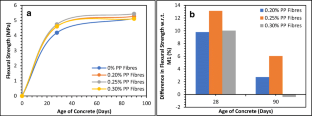

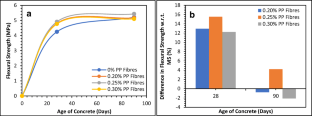

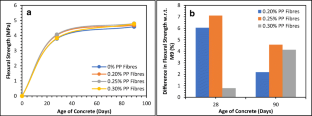

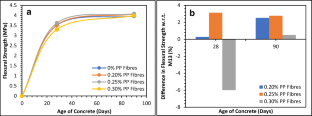

The use of supplementary cementitious materials (SCMs) has increased over the years due to the carbon footprint associated with the production of cement, which contributes to 10% of the total global CO2 gas emissions. This causes an increase in global warming, and the exponential increase in demand for construction of concrete has caused depletion of natural resources. Furthermore, due to increased urbanisation, large quantities of agro-industrially processed waste materials are generated and dumped into landfills, causing significant land scarcity, environmental issues, and pollution. Therefore, it has become necessary to reduce the CO2 emissions by reducing our dependency on cement as a binder and developing eco-friendly concrete using alternative binders from agro-industrial waste materials. This study utilises Rice Husk Ash (RHA) as SCM and reinforcing with polypropylene (PP) fibres. The cement content is replaced with 5 to 20% RHA with an increment of 5% while reinforcing with PP fibres ranging from 0.20 to 0.30%. Based upon the results, it can be observed that concrete incorporating 15% RHA and reinforced with 0.25% PP fibres achieved better performance than the specimen with no SCM. However, a further increase in RHA content decreased concrete strength, which could not be recovered entirely with the reinforcement of PP fibres, though concrete with higher (20%) RHA reinforced with PP fibres could be used for non-structural and low-cost construction.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

Rice husk ash as a potential supplementary cementitious material in concrete solution towards sustainable construction

Article 12 October 2021

Rice Husk Ash (RHA)—The Future of Concrete

Chapter © 2019

Use of Rice Husk Ash (RHA) as a Sustainable Cementitious Material for Concrete Construction

Chapter © 2018

Explore related subjects

Data availability

Change history

References

- Aggarwal LK (1995) Bagasse-reinforced cement composites. Cem Concr Compos. 17(2):107–12. Available from: https://linkinghub.elsevier.com/retrieve/pii/095894659500008Z. Accessed 03 Oct 2020

- Andrew RM (2018) Global CO2 emissions from cement production. Earth Syst Sci Data 10:195–217. https://doi.org/10.5194/essd-10-195-2018ArticleGoogle Scholar

- Antiohos SK, Papadakis VG, Tsimas S (2014) Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem Concr Res 61–62:20–27 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0008884614000763. Accessed 04 Feb 2021

- Bapat JD (2017) Mineral Admixtures in Cement and Concrete. 1st ed. CRC Press. Available from: https://www.routledge.com/Mineral-Admixtures-in-Cement-and-Concrete/Bapat/p/book/9781138076440

- Becknell NP, Hale WM (2011) Effect of slag grade and cement source on the properties of concrete. Int J Concr Struct Mater 5(2):119–123 Available from: http://koreascience.or.kr/journal/view.jsp?kj=E1CJBL&py=2011&vnc=v5n2&sp=119. Accessed 04 Feb 2021

- Benhelal E, Zahedi G, Shamsaei E, Bahadori A (2013) Global strategies and potentials to curb CO2 emissions in cement industry. J Clean Prod 51:142–161. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0959652612006129. Accessed 18 May 2020

- Benli A, Turk K, Kina C (2018) Influence of silica fume and class F fly ash on mechanical and rheological properties and freeze-thaw durability of self-compacting mortars. J Cold Reg Eng 32(3):2–9 ArticleGoogle Scholar

- Bheel N, Meghwar SL, Abbasi SA, Marwari LC, Mugeri JA, Abbasi RA (2018) Effect of rice husk ash and water-cement ratio on strength of concrete. Civ Eng J 4(10):2373 ArticleGoogle Scholar

- Błaszczyński T, Przybylska-Fałek M (2015) Steel fibre reinforced concrete as a structural material. Procedia Eng 122(Orsdce):282–289 ArticleGoogle Scholar

- BS EN 12390–3 (2019) Testing hardened concrete. Compressive strength of test specimens. British Standards Institution, London

- BS EN 12390-5 (2019) Testing hardened concrete. Flexural strength of test specimens. British Standards Institution, London Google Scholar

- Chao-Lung H, Anh-Tuan BL, Chun-Tsun C (2011) Effect of rice husk ash on the strength and durability characteristics of concrete. Constr Build Mater. Elsevier Ltd 25(9):3768–3772. https://doi.org/10.1016/j.conbuildmat.2011.04.009ArticleGoogle Scholar

- Chen H, Siebenmorgen TJ, Griffin K (1998) Quality characteristics of long-grain rice milled in two commercial systems. Cereal Chem 75(4):560–565 ArticleCASGoogle Scholar

- Chen M, Ren C, Liu Y, Yang Y, Wang E, Liang X (2019) Effects of polypropylene fibre and strain rate on dynamic compressive behaviour of concrete. Materials (Basel) 12(11):1–17 ArticleGoogle Scholar

- Chindaprasirt P, Homwuttiwong S, Jaturapitakkul C (2007) Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr Build Mater 21(7):1492–1499 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061806001334ArticleGoogle Scholar

- Ede AN, Ige AO (2014) Optimal polypropylene fiber content for improved compressive and flexural strength of concrete. IOSR J Mech Civ Eng 11(3):129–135 Available from: http://www.iosrjournals.org/iosr-jmce/papers/vol11-issue3/Version-4/S01134129135.pdf. Accessed 16 Nov 202

- FiberVisions (2020) Sustainability throughout our product lifecycle [Internet]. Fibervisions LP. [cited 2021 Jan 21]. Available from: https://www.fibervisions.com/about-us/sustainability/sustainability-throughout-our-product-lifecycle. Accessed 21 Jan 2021

- Flower DJM, Sanjayan JG (2007) Green house gas emissions due to concrete manufacture. Int J Life Cycle Assess 12(5):282–288. Available from:. https://doi.org/10.1065/lca2007.05.327ArticleCASGoogle Scholar

- Food and Agriculture Organization. Food and Agriculture Organization Corporate Statistical Database (FAOSTAT) [Internet]. Cultivos. 2019 [cited 2021 Jan 29]. Available from: http://www.fao.org/faostat/es/#data/QC. Accessed 29 Jan 2021

- Gartner E (2004) Industrially interesting approaches to “low-CO2” cements. Cem Concr Res 34(9):1489–1498 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0008884604000468. Accessed 04 Feb 2021

- Givi AN, Rashid SA, Aziz FNA, Salleh MAM (2010) Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr Build Mater 24(11):2145–2150. Available from: https://doi.org/10.1016/j.conbuildmat.2010.04.045

- Haridass M, Gunasekaran R, Vijayakumar V, Vijayaraghavan P (2017) Experimental study on concrete with plastic plate fibre reinforcement. Int. J. ChemTech Res. [Internet]. 10(14):74–81. Available from: www.sphinxsai.com

- Hasan A, Maroof N, Ibrahim Y (2019) Effects of polypropylene fiber content on strength and workability properties of concrete. Polytech J 9(1):7–12 ArticleGoogle Scholar

- Huntzinger DN, Eatmon TD (2009) A life-cycle assessment of Portland cement manufacturing: comparing the traditional process with alternative technologies. J. Clean. Prod 17(7):668–75. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0959652608000826. Accessed 04 Feb 2021

- Hussain Z, Md Noor N, Caronge MA (2019) Workability and compressive strength of seawater-mixed concrete containing rice husk ash as supplementary cementitious material. Int J Integr Eng 11(9 Special Issue):192–200 Google Scholar

- International Energy Agency. Global Energy & CO2 Status Report 2019 – analysis [Internet]. Int. Energy Agency. 2019 [cited 2021 Feb 4]. Available from: https://www.iea.org/reports/global-energy-co2-status-report-2019. Accessed 04 Feb 2021

- Jamil M, Kaish ABMA, Raman SN, Zain MFM (2013) Pozzolanic contribution of rice husk ash in cementitious system. Constr Build Mater 47:588–593 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061813004868. Accessed 04 Feb 2021

- Jhatial AA, Inn GW, Mohamad N, Johnson Alengaram U, Hung Mo K, Abdullah R (2017) Influence of polypropylene fibres on the tensile strength and thermal properties of various densities of foamed concrete. IOP Conf Ser Mater Sci Eng 271:012058. Available from:. https://doi.org/10.1088/1757-899X/271/1/012058ArticleGoogle Scholar

- Jhatial AA, Goh WI, Mohamad N, Hong LW, Lakhiar MT, Samad A et al (2018) The mechanical properties of foamed concrete with polypropylene fibres. Int J Eng Technol 7(September):411–413 Google Scholar

- Jhatial AA, Goh WI, Mo KH, Sohu S, Bhatti IA (2019) Green and sustainable concrete – the potential utilization of rice husk ash and egg shells. Civ Eng J 5(1):74 ArticleGoogle Scholar

- Kamau J, Ahmed A, Hyndman F, Hirst P, Kangwa J (2017) Influence of rice husk ash density on the workability and strength of structural concrete. Eur J Eng Res Sci. 30;2(3):36. Available from: http://ejers.org/index.php/ejers/article/view/292

- Khan R, Jabbar A, Ahmad I, Khan W, Khan AN, Mirza J (2012) Reduction in environmental problems using rice-husk ash in concrete. Constr Build Mater [Internet] 30:360–365 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061811006581. Accessed 03 Oct 2020

- Khunthongkeaw J, Tangtermsirikul S, Leelawat T (2006) A study on carbonation depth prediction for fly ash concrete. Constr Build Mater 20(9):744–753 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061805000978ArticleGoogle Scholar

- Krishna NK, Sandeep S, Mini KM (2016) Study on concrete with partial replacement of cement by rice husk ash. IOP Conf Ser Mater Sci Eng 149(1):012109 ArticleGoogle Scholar

- Kulakowski MP, Pereira FM, Molin DCCD (2009) Carbonation-induced reinforcement corrosion in silica fume concrete. Constr. Build. Mater. [Internet]. Mar;23(3):1189–95. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061808002390. Accessed 04 Feb 2021

- Lu C, Wang W, Li Q, Hao M, Xu Y (2018) Effects of micro-environmental climate on the carbonation depth and the pH value in fly ash concrete. J Clean Prod 181:309–317 Available from: https://linkinghub.elsevier.com/retrieve/pii/S095965261830177XArticleCASGoogle Scholar

- Lund P (2007) Impacts of EU carbon emission trade directive on energy-intensive industries — indicative micro-economic analyses. Ecol. Econ. [Internet]. Sep;63(4):799–806. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0921800907001012

- Maddalena R, Roberts JJ, Hamilton A (2018) Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. [Internet]. Jun;186:933–42. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0959652618304505

- Mala K, Mullick AK, Jain KK, Singh PK (2013) Effect of relative levels of mineral admixtures on strength of concrete with ternary cement blend. Int J Concr Struct Mater 7(3):239–249. Available from:. https://doi.org/10.1007/s40069-013-0049-9ArticleCASGoogle Scholar

- Marchetti E. Use of agricultural wastes as supplementary cementitious materials. 2020; Google Scholar

- Meddah MS, Ismail MA, El-Gamal S, Fitriani H (2018) Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. [Internet]. 166:400–12. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0950061818301624. Accessed 04 Feb 2021

- Mehta PK, Monteiro PJM (2014) Concrete: microstructure, properties, and materials, Fourth Edition [Internet], 4th edn. McGraw-Hill Education, New York Available from: https://www.accessengineeringlibrary.com/content/book/9780071797870Google Scholar

- Memon IA, Jhatial AA, Sohu S, Lakhiar MT, Khaskheli ZH (2018) Influence of fibre length on the behaviour of polypropylene fibre reinforced cement concrete. Civ Eng J 4(9):2124–2131 ArticleGoogle Scholar

- Mo KH, Yap SP, Alengaram UJ, Jumaat MZ, Bu CH (2014) Impact resistance of hybrid fibre-reinforced oil palm shell concrete. Constr Build Mater 50:499–507. Available from:. https://doi.org/10.1016/j.conbuildmat.2013.10.016ArticleGoogle Scholar

- Mohseni E, Khotbehsara MM, Naseri F, Monazami M, Sarker P (2016) Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr Build Mater 111:429–439. Available from:. https://doi.org/10.1016/j.conbuildmat.2016.02.124ArticleCASGoogle Scholar

- Muthayya S, Sugimoto JD, Montgomery S, Maberly GF (2014) An overview of global rice production, supply, trade, and consumption. Ann N Y Acad Sci 1324(1):7–14 ArticleGoogle Scholar

- Nair MM, Shetty N, Alva PP, Shetty SD (2018) Effect of sawdust impregnation on long coir fibers reinforced with epoxy matrix. Int J Adv Appl Sci 5(3):67–74 ArticleGoogle Scholar

- Naqi A, Jang J (2019) Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: a review. Sustainability 21;11(2):537. Available from: http://www.mdpi.com/2071-1050/11/2/537. Accessed 04 Feb 2021

- Owaid HM, Hamid RB, Taha MR (2012) A review of sustainable supplementary cementitious materials as an alternative to all-portland cement mortar and concrete. Aust J Basic Appl Sci 6(9):287–303 CASGoogle Scholar

- Panesar DK (2019) Supplementary cementing materials. Dev. Formul. Reinf. Concr. [Internet]. Elsevier; p. 55–85. Available from: https://linkinghub.elsevier.com/retrieve/pii/B9780081026168000034. Accessed 04 Feb 2021

- Paris JM, Roessler JG, Ferraro CC, DeFord HD, Townsend TG (2016) A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. [Internet]. 121:1–18. Available from: https://linkinghub.elsevier.com/retrieve/pii/S095965261600158X

- Phulpoto KB, Jhatial AA, Memon MJ, Sandhu AR, Sohu S (2020) Effect of polypropylene fibre on the strength of concrete incorporating rice husk ash. J Appl Eng Sci 10(1):69–71 Google Scholar

- Qian CX, Stroeven P (2000) Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem Concr Res 30(1):63–69 ArticleCASGoogle Scholar

- Rambabu PV, Varma JG, Ramarao GV (2015) Durability study on rice husk ash for optimum level of replacement of cement in concrete. Int. J Eng Trends Technol 28(3):144–149. Available from: http://ijettjournal.org/2015/volume-28/number-3/IJETT-V28P228.pdf

- Rashad AM (2015) An exploratory study on high-volume fly ash concrete incorporating silica fume subjected to thermal loads. J. Clean. Prod. [Internet]. Jan;87:735–44. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0959652614009482

- Rashad AM, Zeedan SR (2011) The effect of activator concentration on the residual strength of alkali-activated fly ash pastes subjected to thermal load. Constr. Build. Mater. [Internet]. Jul;25(7):3098–107. Available from: https://linkinghub.elsevier.com/retrieve/pii/S095006181000735X

- Rashad AM, Bai Y, Basheer PAM, Milestone NB, Collier NC (2013) Hydration and properties of sodium sulfate activated slag. Cem. Concr. Compos. [Internet]. Mar;37:20–9. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0958946512002466

- Rodríguez de Sensale G (2006) Strength development of concrete with rice-husk ash. Cem. Concr. Compos. [Internet]. 28(2):158–60. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0958946505001022

- Salas A, Delvasto S, de Gutierrez RM, Lange D (2009) Comparison of two processes for treating rice husk ash for use in high performance concrete. Cem Concr Res 39(9):773–778. https://doi.org/10.1016/j.cemconres.2009.05.006ArticleCASGoogle Scholar

- Sanjuán MÁ, Estévez E, Argiz C, del Barrio D (2018) Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. [Internet]. 90:257–65. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0958946517308582

- Shetty MS (2005) Concrete Technology Theory & Practice. S. CHAND & Company, Ram Nagar Google Scholar

- Shi X-L, Yang H, Tao M, Zhang W (2013) Sulfonic acid-functionalized polypropylene fiber: highly efficient and recyclable heterogeneous Brønsted acid catalyst. RSC Adv. [Internet]. 3(12):3939. Available from: http://xlink.rsc.org/?DOI=c3ra23187a

- Suhendro B (2014) Toward green concrete for better sustainable environment. Procedia Eng 95:305–320 Available from: https://linkinghub.elsevier.com/retrieve/pii/S1877705814032494ArticleGoogle Scholar

- U.S. Geological Survey (2018) Minerals Yearbook Volume III: area reports—international—Asia and the Pacific [Internet]. Available from: https://www.usgs.gov/centers/nmic/asia-and-pacific#pak. Accessed 30 Jan 2021

- U.S. Geological Survey (2019) Mineral commodity summaries 2019 [Internet]. . Available from: https://www.usgs.gov/centers/nmic/mineral-commodity-summaries. Accessed 30 Jan 2021

- Valipour M, Yekkalar M, Shekarchi M, Panahi S (2014) Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J Clean Prod 65:418–423 Available from: https://linkinghub.elsevier.com/retrieve/pii/S0959652613005167ArticleCASGoogle Scholar

- Wei J, Meyer C (2016) Utilization of rice husk ash in green natural fiber-reinforced cement composites: mitigating degradation of sisal fiber. Cem Concr Res 81:94–111. https://doi.org/10.1016/j.cemconres.2015.12.001ArticleCASGoogle Scholar

- Wu Z, Shi C, He W (2017a) Comparative study on flexural properties of ultra-high performance concrete with supplementary cementitious materials under different curing regimes. Constr Build Mater 136:307–313. https://doi.org/10.1016/j.conbuildmat.2017.01.052ArticleCASGoogle Scholar

- Wu Z, Shi C, He W, Wang D (2017b) Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem Concr Compos 79:148–157. https://doi.org/10.1016/j.cemconcomp.2017.02.010ArticleCASGoogle Scholar

- Xi F, Davis SJ, Ciais P, Crawford-Brown D, Guan D, Pade C, et al. (2016) Substantial global carbon uptake by cement carbonation. Nat. Geosci. [Internet]. 9(12):880–3. Available from: http://www.nature.com/articles/ngeo2840

- Yang K-H, Jung Y-B, Cho M-S, Tae S-H (2015) Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J Clean Prod 103:774–783 Available from: https://linkinghub.elsevier.com/retrieve/pii/S095965261400239X. Accessed 04 Feb 2021

Acknowledgements

The authors would like to acknowledge and appreciate the support received from the Department of Civil Engineering, Mehran University of Engineering and Technology, Shaheed Zulfiqar Ali Bhutto Campus, Khairpur Mirs’, Pakistan.